How to Convert Production Order to Planned Order Again

A production guild defines which material is to be processed, at which location, and at what time and how much quantity is required. It too defines which components and sequence of operations are to exist used and how the order costs are to be settled.

- Planned orders are results of running MRP. Shortages of materials that are prepare to internal procurement will create planned orders, which tin be converted into product orders. Production orders are "difficult copies"; they cannot be adjusted by an MRP run anymore.

- BOM and routing information of the materials are copied into the production order which determines the list of components and operational data in the lodge.

- Planned Costs also gets updated in the product society via component price and routing action price.

- Y'all can run an availability bank check on production orders which determines any missing components in the order and so that you can bring that missing component for the order execution at store floor.

- You can impress the production gild for shop flooring which indicates the list of components to be consumed and what kind of operations to be performed in sequence at the work heart.

- After you have physically produced the textile, you can declare the production through order confirmation which updates the activities price such equally machine running price, labor cost on the order.

- You can determine to automatically do the backflush (consumption) of components during society confirmation according to the BOM. The consumption will reduce the inventory of components and information technology is carried out with movement blazon 261 in SAP.

- Yous can also post goods receipt of the material automatically during order confirmation. Goods receipt would increment the inventory of the material, and it is carried out with movement blazon 101 in SAP.

- Subsequently Lodge Confirmation, all the cost such as the price of components and activity cost will exist debited on the order, and one time you post appurtenances receipt, costs will be credited on the social club.

- One time, production guild is fully confirmed and delivered, or business has decided not to execute that order, so it needs to be technically closed which means order will no longer be considered in MRP run and volition be deleted from stock/requirement list. Order reservation on components volition also exist deleted.

In this tutorial- you lot volition learn

- How to Create and release Production Lodge

- How to Create Production Order by converting planned order

- How to Change product Order

- How to ostend production order

- How to TECO (technically complete) production gild

How to Create and release Production Social club

Production Order cosmos is required to produce the material and consume the components which are used, and information technology also specifies the sequence of operations to exist performed at the work center.

The release of order signifies that the order is ready to be executed at the shop floor. You can practise an automatic release of order also during creation mode by using relevant production scheduling profile in the material master with machine release indicator set.

Step 1) From SAP Easy access screen open transaction CO01

-

Enter the material code for which production lodge needs to be created.

- Enter Institute Lawmaking.

After filling in all the fields, click![]() or printing Enter to go to the next screen.

or printing Enter to go to the next screen.

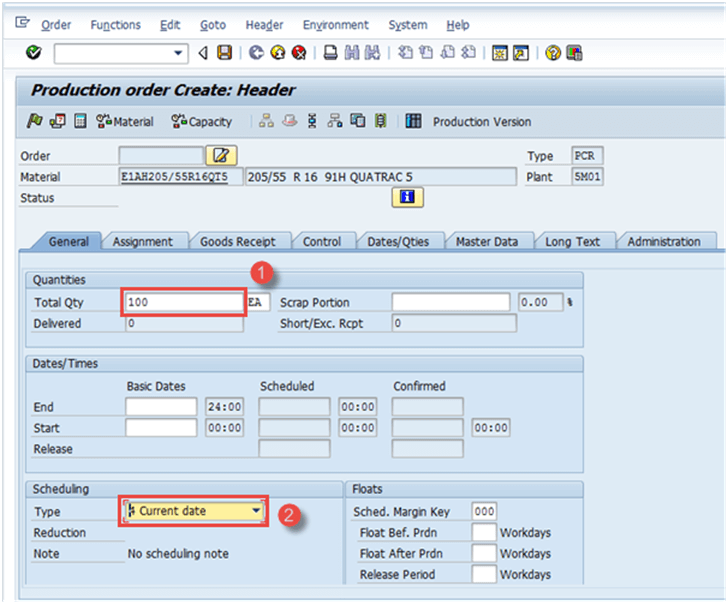

Step ii) In this Screen

- Input the order quantity.

- Select the option"current date" in scheduling sub-screen.

After filling the entire fields printing click ![]() to confirm, the system will and then re-create BOM and Routing information in the guild.

to confirm, the system will and then re-create BOM and Routing information in the guild.

Step three) In the same screen,

-

Click

to release the order. The following message will appear in the lesser left corner:

to release the order. The following message will appear in the lesser left corner: .

.

-

Click

to check material availability. The organization will show the bulletin regarding the availability of components.

to check material availability. The organization will show the bulletin regarding the availability of components.

Notation: You can also decide non to release the lodge if there are missing parts constitute in availability checks.

Click button ![]() to save, the following message will show in the bottom left corner:

to save, the following message will show in the bottom left corner: ![]() .

.

How to Create Production Order by converting Planned Club

Planned orders are the result of MRP run and should be converted to production lodge for further execution procedure.

You cannot directly declare production using planned orders and, therefore, it needs to be converted to Production Order.

One time, planned order is converted to production order, planned order gets deleted from the system and is no longer available to exist considered in MRP (Material Requirement Planning).

Stride 1) From SAP Easy access screen open transaction MD16

- Select radio push "MRP controller" from the list, which is a group of materials.

- Press right mark sign on top or press enter from your keyboard.

The arrangement volition show the screen as beneath.

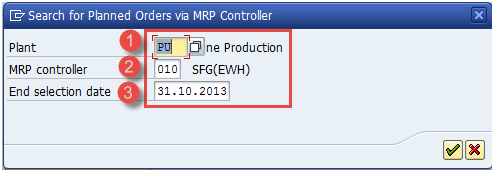

Step 2) In this screen, nosotros will fetch the planned orders based on MRP controller and selection dates.

- Enter plant code.

-

Enter MRP controller

-

Enter end selection engagement till all planned orders will be extracted.

Click right mark sign from the lesser or enter from the keyboard to move to the next screen.

Step iii)In this screen,

- Select the filigree for which you want to convert the planned orders

-

Printing "convert to production order" button for the conversion.

Production orders volition be created after conversion of planned orders.

How to Change production Order

You might require to change product order incase if your business wants to change some planning quantity or if BOM/Routing has been inverse later the order has already been created.

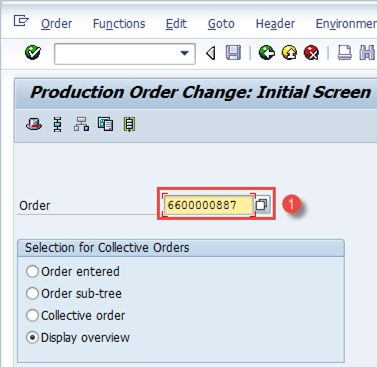

Stride 1) From SAP Piece of cake access screen open transaction CO02

-

Enter production order number which you want to alter.

In the same window you can see "Display Overview" push is selected, it is selected by default.

After filling in all the fields, click ![]() to go to the side by side screen.

to go to the side by side screen.

Step ii) In this screen, the order volition be modified.

- Alter the Social club quantity to 9000 or whatever your requirement is as shown below.

After finishing all modifications, click button ![]() to save the order. The system will show a message like

to save the order. The system will show a message like ![]() Gild number saved 6600000887 at the lower left corner.

Gild number saved 6600000887 at the lower left corner.

How to confirm production order

Step 1) From SAP Piece of cake admission screen open transaction CO15, three activities occur at the same time with confirmation.

- Generate confirmation document

- Eat raw materials or semi-finished goods

- Good receipt of finished appurtenances or semi-finished goods

- Enter Production club number

Afterward filling in all the fields, click ![]() to go to the next screen

to go to the next screen

Step 2) In this screen, nosotros will enter the actual yield quantity to be confirmed.

- Enter the yield quantity which is the produced quantity you want to declare

- Printing Appurtenances Movement button at the elevation to check the automatic goods movement happening along with confirmation

Stride 3) In this screen, you will see the goods receipt of parent material and goods effect of components.

If the control primal of the final operation in the gild specifies automatic appurtenances receipt, the system automatically posts the produced textile to unrestricted stock.

Automatic goods receipt can besides be activated by the production scheduling profile in the material masterwork scheduling view.

If you confirm an order with components that have the Backflushing indicator fix in the cloth chief MRP1 view, the system automatically posts a goods issue (GI) for these components.

- Auto Goods receipt (GR), production of material carried out using movement blazon 101.

-

Machine Goods outcome (GI), consumption of components carried out using movement type 261.

Click push button![]() to save.

to save.

The system volition testify a bulletin like![]() at the lower left corner, to hint how many goods motility are posted successfully or failure.

at the lower left corner, to hint how many goods motility are posted successfully or failure.

Failed goods movements due to a deficit of stock for consumption are reprocessed manually.

How to TECO (technically consummate) production lodge

Technical completion of the order is required when production society is either fully delivered, or information technology is not to be candy further at shop flooring.

After technical completion order condition changes to TECO, no further goods movement tin can be done against the order.

Society is no longer available in MRP run and gets deleted from stock/requirement listing.

The controlling section can and so conduct out the variance calculation on the production Order after TECO condition.

Step 1) From SAP easy admission, open transaction CO02

- Enter the guild number which you desire to TECO.

Click![]() to next screen after filling all fields,

to next screen after filling all fields,

Step two) In this screen, we will run into how to place production order to TECO status,

- Click in bill of fare Function-> Restrict processing ->complete technically System will bear witness message in status- TECO

- System will prove bulletin in condition- TECO

Troubleshooting

-

BOM and Routing must exist before cosmos of production social club else it will not exist copied into the production order and can cause issues in planned costs updation and consumption of components during confirmation process thereby impacting the inventory of the components.

-

Product order must be released before doing club confirmation every bit the released status of the club allows confirmation to happen.

-

If you receive any Bookkeeping error during goods movement in the confirmation process, then ensure the correct valuation class is ready in the material chief Accounting view or contact Finance team.

-

Ensure that standard cost for the material is updated to avoid whatever costing related errors such as activity price missing etc. during production gild confirmation.

-

If some goods movement gets failed during confirmation process due to the stock deficit, then you should process them separately once components are brought to stock.

eckhardtupoopturt.blogspot.com

Source: https://www.guru99.com/production-order-sap-pp.html

0 Response to "How to Convert Production Order to Planned Order Again"

Post a Comment